Purpose of clean room air conditioning; In addition to minimizing dust particles, it is to keep the temperature and humidity required for the operations to be performed in this room at a certain level and to ensure reliability. Since the clean room air conditioning system must operate every day of the year and around the clock, another issue that businesses should not ignore is that they should use systems with low energy consumption.

Why Use Clean Room Air Conditioning?

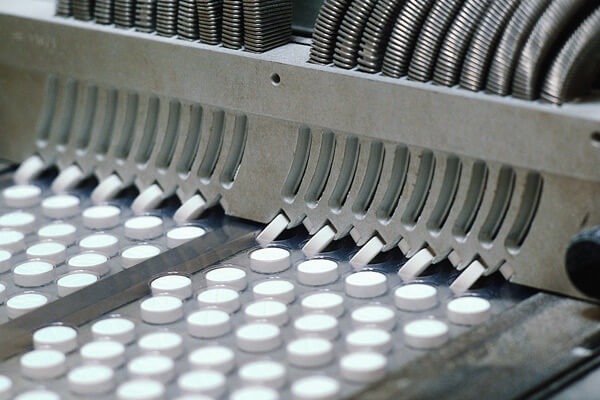

In Advanced Technology Production: It should be used to improve the quality of the manufactured product, to develop new products, to reduce the use of materials in products, to increase productivity in production.

In the production of hygienic products: Bacteria, mold etc. are added to the products. It should be used to prevent contamination of microorganisms, to prolong the shelf life of products, to prevent contamination of foreign substances.

In Health Institutions: It should be used to prevent possible infection situations, to prevent the spread of infectious diseases, to minimize the use of antibiotics.

What are the Duties of Cleanroom Air Conditioning?

To prevent dust particles from entering, to provide the desired humidity level, to provide the temperature that will be sufficient, to ensure that the noise level is kept at the lowest level in order to prevent concentration impairment especially in the operating rooms,

To ensure that the plus or minus pressure set depending on the work to be done in the room remains at a constant level, to prevent harmful substances that may come out of the product from harming people,

To minimize the waste of energy, to keep the conditions at a reliable level in the production environment or in the environments that will affect human health.